In the last years centralised softening of drinking water is increasingly being discussed and realised - in particular in areas with a high hardness level (greater than 3.5 mmol/l). In particular, the supply of water in the hardness range 3 or 4 leads to lime scales and thus to negative effects for consumers:

Lime scales

- causes an increase in the cleaning work required at surfaces,

- results in a notable increase of energy consumption at heat exchangers,

- notably increases the amount of detergent used,

- reduces the service life of piping and fittings.

Partially increased heavy metal emissions from the drinking water installations are furthermore ecologically relevant.

For this reason consumers often use local on-site water softening devices that usually function according to the cation exchanger principle. However, these systems often cause high follow-up costs in the range of € 0.8 to 1.0/m³ of decalcified water (depreciation across 10 years, salt consumption and maintenance). Furthermore, the water consumption increases due to the regeneration of the resins and the waste water is polluted with regeneration salt.

The better way is centralised softening in the water work for which various processes are available:

- Slow decarbonisation (SDC)

- Rapid decarbonisation (RDC)

- CARIX process (ionexchange process)

- Nanofiltration process (NF) and

- Reverse osmosis (RO)

Relevant factors for the choice of the process are, in addition to the composition and the quantities of the contents, in particular also the pre-treatment, the treatment capacity, the recycling of the waste materials, the conditions for the discharge of the unavoidable waste water as well as any post-treatment that may be required.

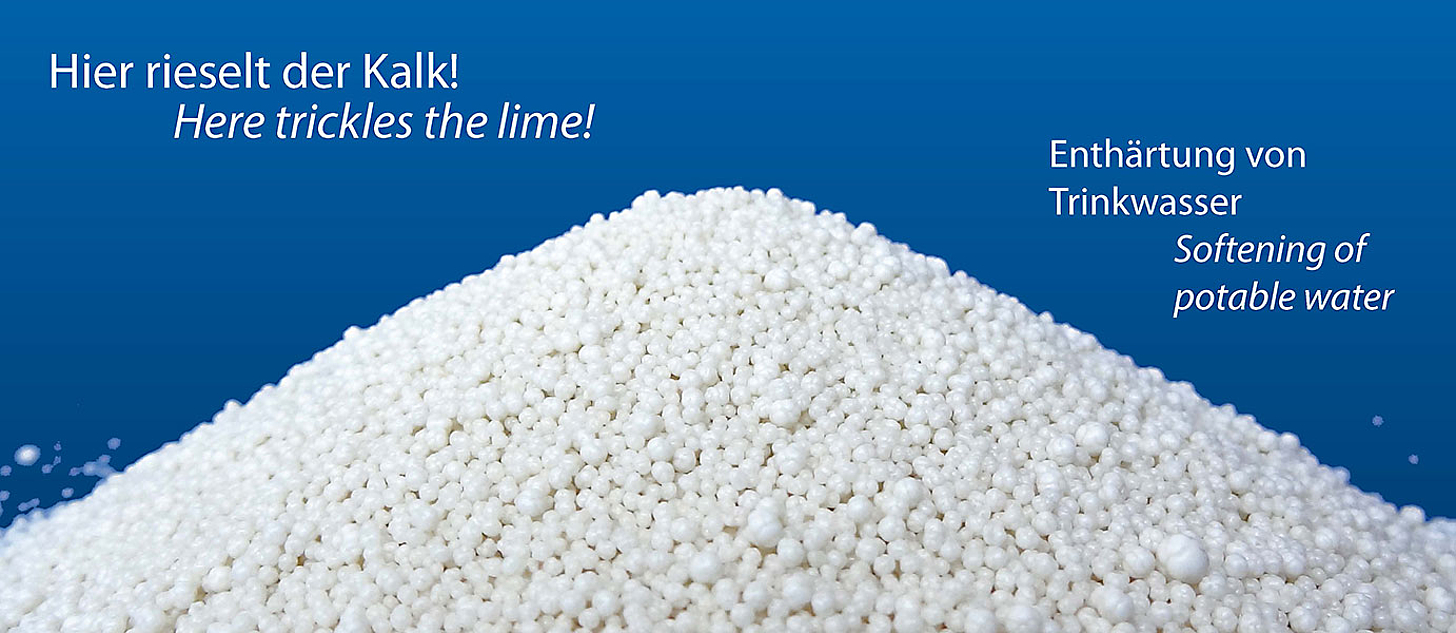

The picture above impressively shows how much lime can be dissolved in water. The pellets shown here come from a decalcification plant using the rapid decarbonisation process. The high-purity pellets can be used in the building materials industry or in agriculture as soil improvers.

We specialize in rapid decarbonization and innovative membrane technologies such as low pressure nanofiltration (LPRO) and reverse osmosis (RO).