Oxygen is the most important oxidation agent in the context of water treatment. In addition, a sufficient oxygen content is relevant for the drinking water quality and for the stability and corrosion prevention in the network. To form a sufficient protective coating (limescale rust protection coating) in the pipe system, the oxygen content of the water should not fall below 5-6 mg O2/l.

Depending on the altitude above sea level, air contains a maximum of approximately 21 % oxygen, 78 % nitrogen and 1 % other gases. Each of these gases forms its own pressure due to gravity, the so-called partial pressure. The sum of the partial pressures gives the total pressure of the gas mixture. An air pressure of 1 bar is therefore the sum of the partial pressures of oxygen (about 0.21 bar), nitrogen (about 0.78 bar) and other gases (about 0.01 bar).

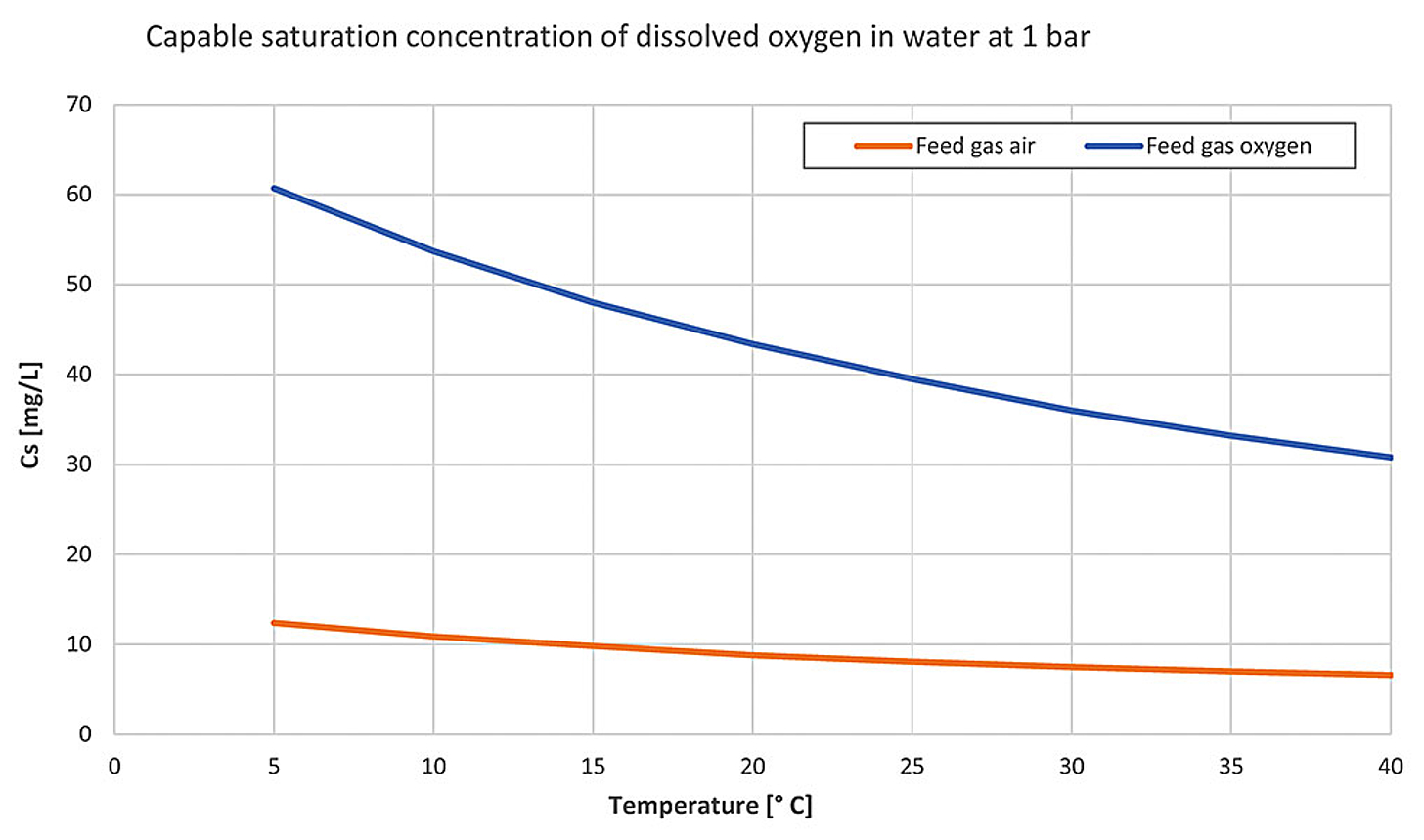

In the aeration of water (air oxidation), the gases oxygen and nitrogen compete with each other due to their different partial pressures. The maximum oxygen saturation is therefore limited to approx. 12 mg/l (8°C) or 10 mg/l (15°C) depending on the temperature of the air (the higher the temperature, the lower the oxygen saturation).

When using oxygen or technically produced oxygen with a concentration of 93 - 95%,

- up to 4.5 times higher saturation can be achieved,

- energy-intensive mixing systems and large oxidiser tanks can be omitted,

- better oxidation is achieved,

- the venting systems can be dimensioned considerably smaller.

For this reason, we only use technical oxygen for oxygen enrichment. This is generated in high quality directly on site by means of oxygen generators. The gas mixture is finely filtered through several graduated filters and contains only a small amount of nitrogen. The correct quantity is dosed by means of mass flow controllers.

Oxygen generators in three lines

Oxygen generators work with compressed air as feed gas. In order to ensure an economically efficient operation, oxygen generation systems should be dimensioned according to the individual case.

The compressed air must be specially treated to produce oxygen. In addition to drying, filters for the separation of solids as well as for the adsorption of gaseous substances must be considered.

We would be pleased to support you in calculating the actual oxygen demand as well as in the optimal configuration of a system for use in the water technology sector.

Please ask us!