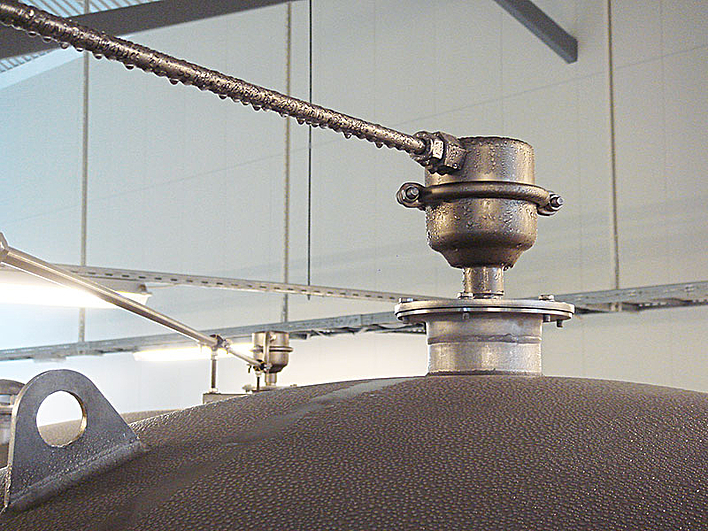

Air always contains a specific amount of water vapour. There is therefore a latent risk of condensation forming on cold surfaces of water-bearing system components in elevated tanks, waterworks, wells and pumping stations, etc.

Moisture can also build up in walls as a result of water vapour diffusion, causing significant structural damage. Continuous dehumidification to a maximum permissible value reliably prevents condensation and thus helps to preserve the value of the often high-quality system technology.

Condensation

causes in particular:

• Corrosion and damage (rust) on mechanical and electrical equipment

• Electrical faults due to short circuits and leakage currents up to and including system failure

• Moisture penetration damage and corrosion on the building structure

• Mold formation on surfaces and walls

• Unhygienic conditions in high-level tanks, pumping stations, shafts, waterworks etc.

Condensation air dehumidifiers or adsorption air dehumidifiers can be used for air dehumidification in waterworks. Dehumidifiers based on the condensation principle generally work very economically. In addition to optimum dehumidification, air circulation also plays an important role - particularly in large-volume and high buildings.

Dehumidifiers for waterworks

The series HDE air dehumidifiers were developed for both commercial use and for use in waterworks. For this reason, these dehumidifiers have a corrosion-resistant stainless steel housing (Protection Class IP54). The generously dimensioned ventilators provide high-volume air circulation and therefore excellent dehumidification performance even in large and high rooms. Full electronic control guarantees an efficient dehumidification process even at low operating temperatures.