Overview

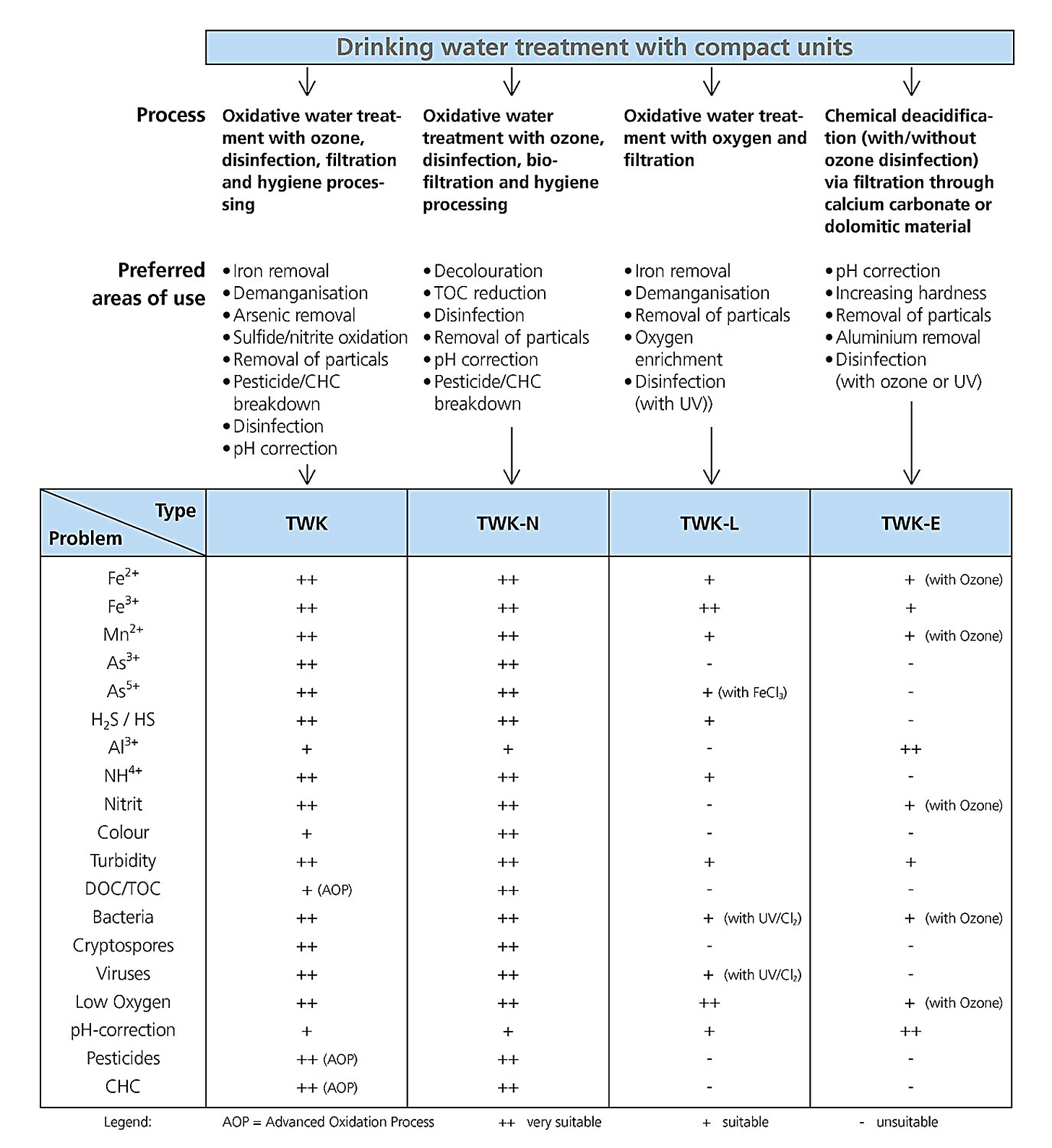

The HYDROZON® drinking water compact units are suitable for almost all areas of use relating to drinking water treatment with filtration. Problem-oriented, fully-automatic systems can be implemented utilizing modular design.

A rough distinction can be made between the following treatment processes:

Drinking water compact systems TWK

With our HYDROZON® drinking water compact systems (TWK) you realize an near-to natural method of treating and disinfecting different types of raw water into best drinking water.

HYDROZON® drinking water compact systems can be integrated both into new systems and, thanks to their compact size, subsequently into existing systems. At a comparison of costs (investment costs + operating costs) HYDROZON® drinking water compact systems are usually notably less expensive than conventional ozone system technology.

Structure of the compact drinking water treatment plants

Compacte drinking water treatment plants are distinguished by:

- Modular structure

- Compact performance units from 5 to 200 m3/h filter performance, in group operation any quantities can be realised

- Small space requirement

- Operational reliability via perfected process technology, high-quality materials and tried-and-tested control technology

- Patented ozone production and mixing in the closed hydraulic system

- Optimised venturi / injector system with full-flow mixing for efficient ozone or oxygen introduction (for pure iron removal)

- Easy operation through touch panel and programmable logic controller (PLC), (operation limited to monitoring)

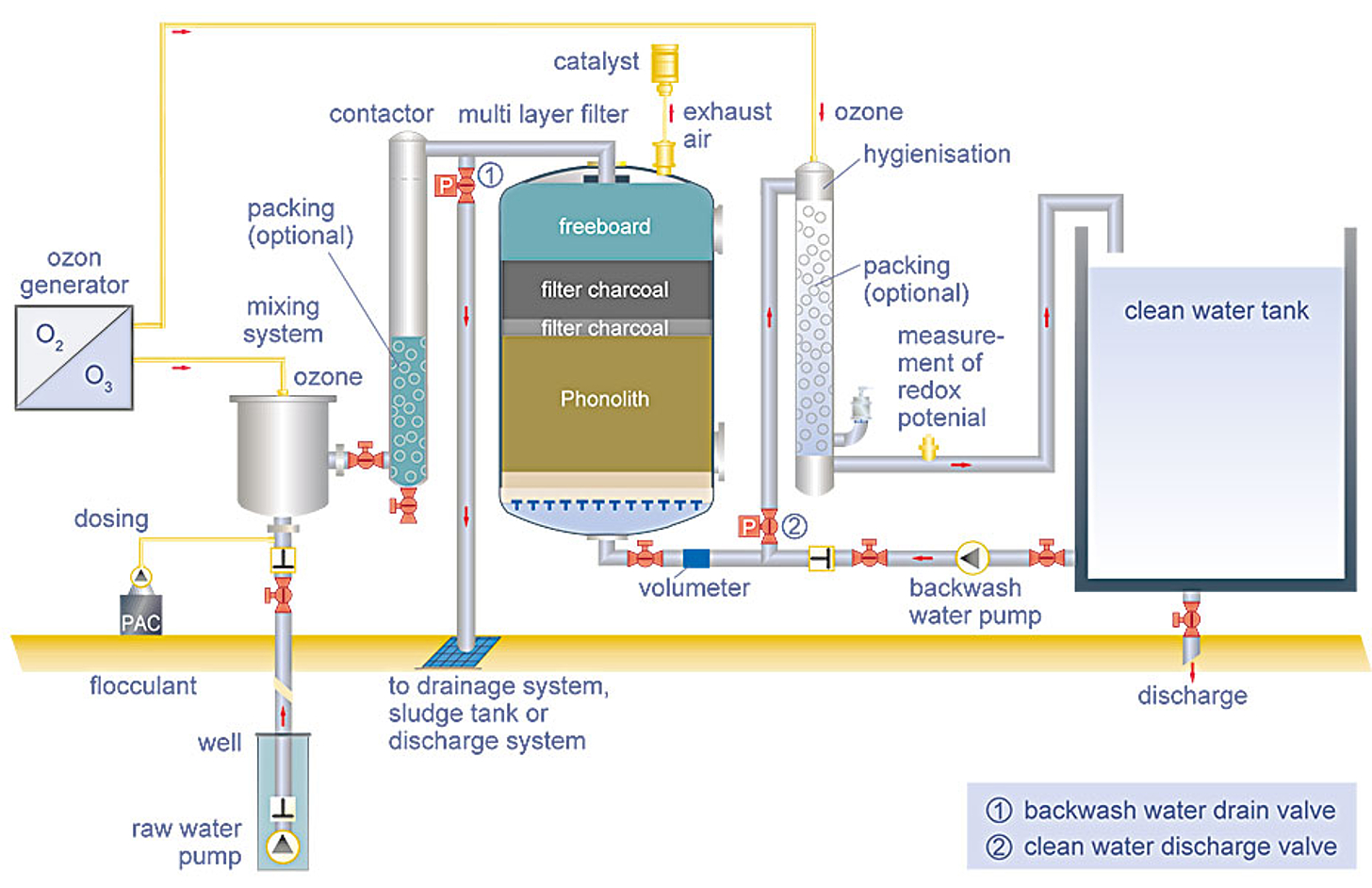

The basic process at compact drinkingwater treatment plants

Drinking water treatment in the HYDROZON® method is as a rule carried out to the following basic process:

Filter-based separation of colloid disperse particles is optimised by adding flocculants to the raw water. Ozone supports flocculation and thus increases the filter performance. Dissolved organic substances are mineralised by oxidation with ozone or split up into low-molecular biologically assimable groups. Inorganic compounds such as iron, manganese, arsenic, etc. are oxidised to complexes which can be filtered.

Oxidation under exclusion of chlorine avoids the formation of Tri-Halogen-Methane (THM) and reduces their formation potential. In optimised multi-layer filters the oxidised compounds and flocculated complexes are held back.

In the ozone-free environment of the filter bed the ozone-split assimilable organic groups are oxidised biologically.

The final hygiene processing of the filtered water with residual ozone after the biologically active multi-layer filter or with ultraviolet light ensures hygiene in the pure water until the consumer is reached. The redox potential, measured in the pure water after hygiene processing, indicates the measure of treatment and informs on the ozone requirements of the raw water.

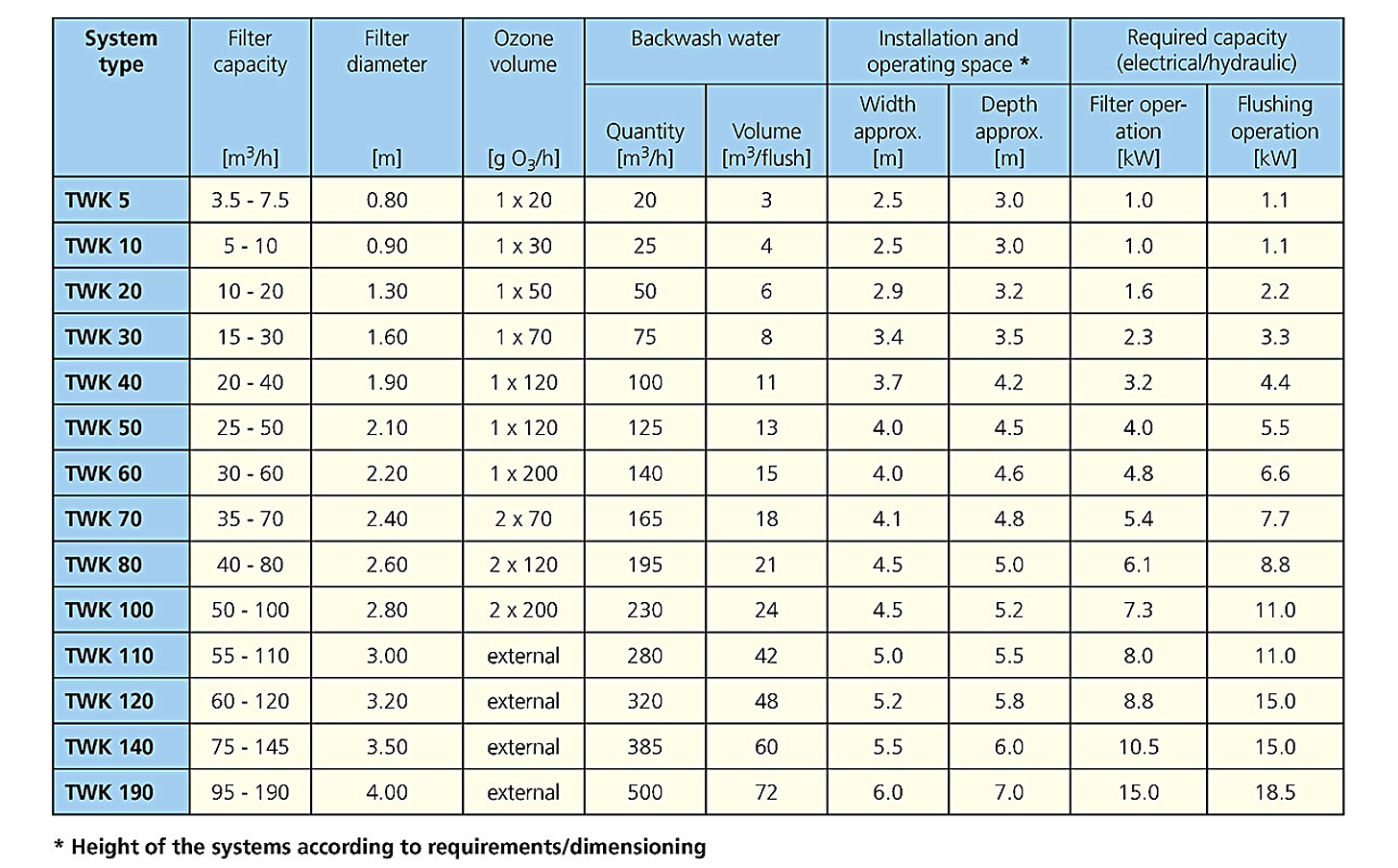

Performance units of the compact drinking water systems

HYDROZON® drinking water compact systems are available in standardised performance units. Greater performance capacities are realised by several units in parallel or special forms. In the case of extended process technology the systems are positioned in series.

The stated filter performances are based on a filter speed of 15 m/h.

We advise that you always send us an object-specific enquiry. The dimensions specified here are not legally binding under any circumstances. Larger plants are dimensioned object-specifically. We are looking forward to your enquiry!

Aeration systems with compact drinking water treatment plants

Aeration systems are suitable for the treatment of oxygen-reduced groundwater containing iron and minimal amounts of manganese. We cover this field in an ideal way using the simplified compact unit technology.

A high-efficiency gas-mixing system is implemented instead of using ozone generators. While the iron removal and oxygen enrichment usually occur relatively problem free, the removal of manganese requires either catalytic filter materials or biological manganese oxidation. For the latter, inoculation of the filter material may be necessary.

Aeration systems are generally geared toward standard TWK systems.We do, however, recommend having the manufacturer design a system which meets the particular needs of the situation.