Ozone system technology by experts

Ozone systems in the field of water treatment are complex systems for whose correct process engineering a wide range of experience is important.

Our range of services include

- the optimum design and planning of ozone systems

- the optimum design and planning of PSA systems for supplying oxygen

- manufacturing and delivery

- mounting and commissioning

- servicing and maintenance.

Only oxygen is used as feed gas for the generation of ozone in order to avoid the formation of nitric oxide. In ozone systems up to approx. 5 kg / h, the oxygen is generated in so-called PSA plants on site. For large scale plants, liquid oxygen (LOX) is usually more favorable.

In addition to self-manufactured air cooled systems with plasma technology with an output of up to 1 kg/h we use exclusively systems manufactured by other well-known manufacturers - in particular at large systems.

Areas of use for ozone systems

- Drinking water treatment (disinfection and oxidation)

- Swimming pool water treatment

- Industrial water treatment, process water treatment

- Beverage industry, bottle rinser

- Circulation water treatment

- Cooling water treatment

- Wastewater treatment for removal of traces / trace substances

- etc.

HYDROZON® oxidator units (POX)

The HYDROZON® oxidator units (POX) were designed especially for use in the field of water treatment.

These units are distinguished by:

- Modular structure of all required operating components

- Operational reliability via perfected process technology, high-quality materials and tried-and-tested control technology with a PROFIBUS connection

- Efficient, aircooled ozone production

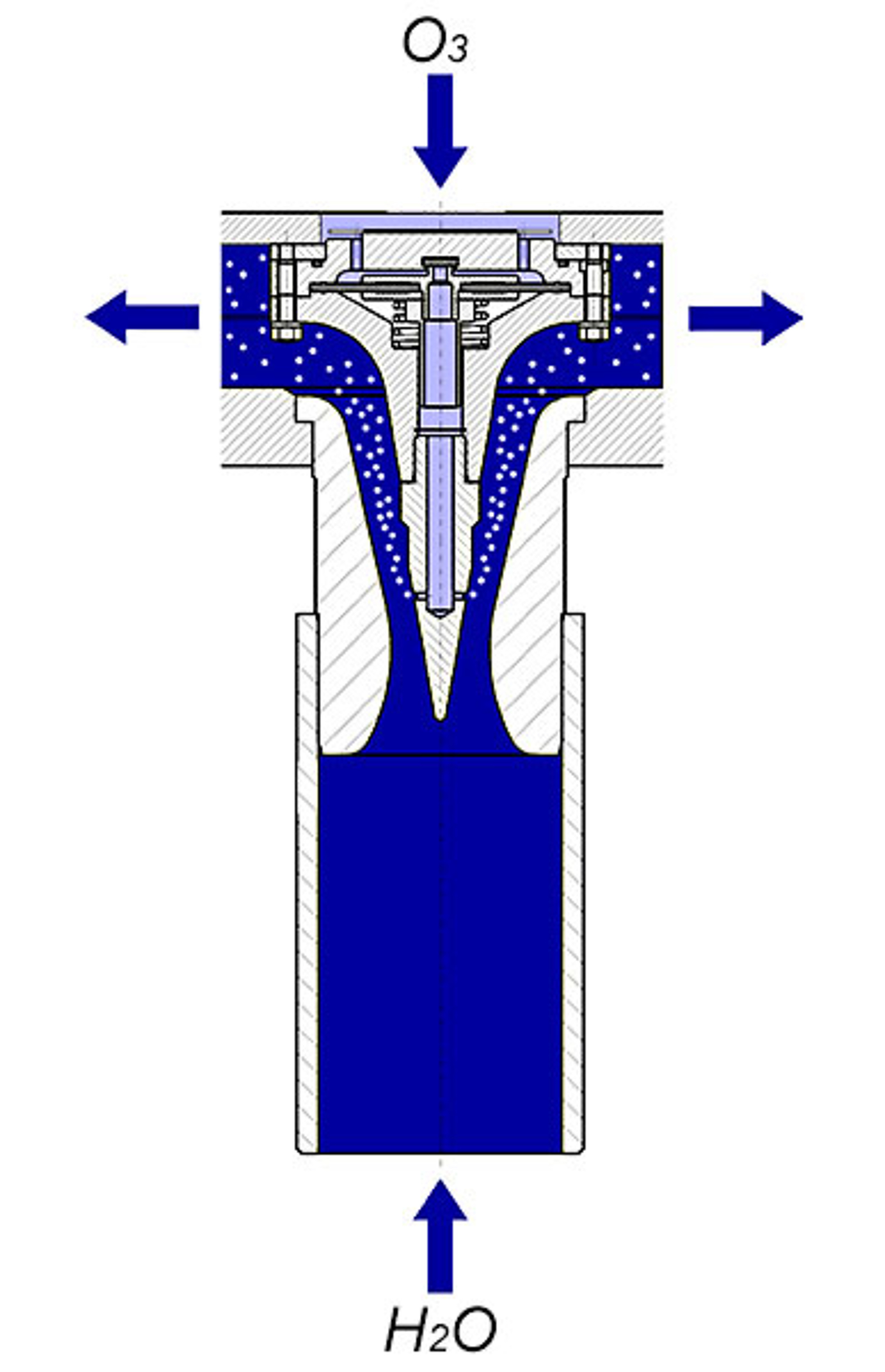

- Optimised venturi / injector system with full-flow mixing for efficient ozone supply

- Easy operation via a microprocessor-based control system

- Continuous setting (or regulation) of the ozone quantity

Possible areas of use:

Drinking water treatment, recyclable-water treatment, cooling-water treatment in ventilation and air-conditioning systems, upgrading existing systems, rinser systems, oxidation systems.

Venturi injector mixing-in systems

Due to its high oxidation potential, ozone produces a very fast oxidation of organic and inorganic water components. Prerequisite for a good reaction is, however, that the ozone-gas mixture is mixed intensively and effective with the water.

Mixing-in the ozone in the water is usually done with highly efficient venturi injector combinations with which treatment of the full flow or in bypass is possible. The optimal hydraulic adjustment to the respective water flow to be treated is effected through different sizes and combinations.